Uganda Breweries: Procuring from local communities to drive change in Uganda

Consuming up to 10 litres of alcohol per person per annum, Uganda has become a country of significant growth for the adult beverage industry. Each year, up to a million Ugandans reach legal purchase age, fuelling a market full of untapped potential for new and developing businesses.

Focused on delivering high-quality products, from international brands such as Guinness and Tusker to popular local products Bell Lager, Uganda Waragi, Senator, Ngule and much more, Uganda Breweries Limited (UBL) strives to tap into the tastes and demands of its consumers.

“Whilst spirits continue to grow, the informal beer sector represents 60% of alcohol consumption in Uganda. There’s a huge opportunity for us to recruit consumers into our product segments,” explains Joshua Muwema, Head of Procurement.

Raw local sourcing agenda

The company seeks to become one of the best performing, respected and, more importantly, most trusted consumer goods company in Uganda.

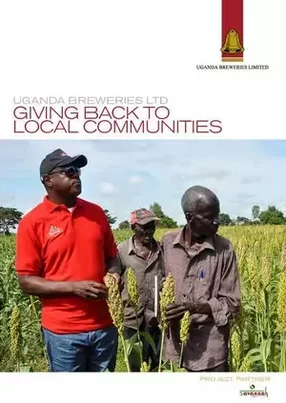

In spearheading the implementation of sustainable, domestic value creation across UBL’s supply chain, UBL has sought to transform its business through placing increased emphasis on procuring raw materials from local communities to improve the lives of Ugandan citizens.

Through UBL’s local raw materials (LRM) agenda, the company has sought to nurture partnerships with local suppliers and farmers. UBL provides farmers with the necessary seeds to grow the grain for our processes. We educate them on how to achieve the right quality and subsequently provide the market once the crop is harvested,” says Muwema.

This remains an area of immense pride for Muwema, and in 2015 the company reached a total of approximately 17,000 farmers under its LRM agenda, and in turn, benefitted over 25,000 households countrywide.

“Our collaboration with Kakira Sugar (part of The Madhvani Group), for example, has enhanced our ability to avail our consumers with affordable quality beverages resulting from a tax benefit from the government,” Muwema explains.

UBL’s decision to appoint Savannah Commodities as a single aggregator for sourcing its local raw materials is projected to also bring immense benefits to both the company and its farmers.

The farmers have a one stop centre where all produce is received, processed and stored hence guaranteeing quality. The agro processing facility sits beside a fertiliser blending plant that provides cheap affordable fertiliser to farmers, boosting productivity on their land.

“With Savannah being our partner in extension delivery, we have seen more demo farms established while an opportunity arose out of this marriage for us to expand barley growing areas to the south western frontier of Kigezi region which adds to the communities that benefit from working with UBL,” comments Muwema.

As the business thrives, its engagement with communities doesn’t stop at its commercial activities but undertakes a number of corporate responsibility initiatives. Whilst many communities in Uganda lack access to clean water, UBL’s Water for Life Programme has worked to deliver essential access to clean water facilities, improved sanitation levels and provided a significant long-term impact.

With regards to environment conservation, UBL staff have undertook the E-Green Initiative contribute to the restoration of Uganda’s forest cover through tree planting. Most recently, the company has been in partnership with National Forestry Authority (NFA) and Wild Wide Fund (WWF), restored 109 hectares of forest cover to the Navugulu Forest Reserve allowing for the forest to serve its purpose as a catchment for Lake Victoria, thus contributing to less pollution upstream.

Driving productivity

Throughout its ambitious five-year plan, UBL has witnessed a significant improvement in the rollout of various Capex projects as its brewery continues to expand.

“Productivity is an engine for growth for us because, for every penny that we save, we look at how much we can plough back into the business,” comments Muwema.

“We are currently installing a state-of-the-art bottling line at the distillery. This line is fully automated and will be deployed along with associated utilities and civil works which include a brand-new warehouse and other amenities. This will be launched in June this year and will help us roll out products that will meet the ever-growing customer demands.

“We’ve seen a lot of growth on the spirits side of the business and are investing where we see a future,” he adds.

“On the beer side of the business, we have currently maxed out the production capacity of 1.2mn h/litres. The limiting factor being the packaging line and beer storage.

“Our plan is to invest in packaging and storage capacity to increase production by 50%. This is work in progress and is planned for the next financial year.”

To further support its ongoing expansion, UBL has also developed strategic partnerships with logistics suppliers to drive efficiencies whilst bringing down cost. “Efficiencies in transport and warehousing are key in maintaining positive COGS which in turn helps us to price the product at an affordable price point to the consumer,” says Muwema.

Partnering with DHL East Africa has seen UBL outsource its distribution, inventory management and warehousing operations, thus unlocking increased value and ensuring the products are at the right place, the right time and at the right price.

“DHL shares in our vision and in 2018 have embarked on an expansion program at its Luzira warehouse facilities in order to meet UBL’s growing warehouse capacity demands. Additionally, DHL is aggressively looking at their existing fleet with a plan to refresh and expand the existing fleet and forklifts as well, to improve efficiency and manage UBL’s increased production volumes,” he adds.

“We did something similar with Mansons, who is also a major transporter but on longer routes. We have structured a performance contract with them that gives us more, without necessarily driving up costs. Within this 3PL contract, we have included bonus malice clause, wherein we discuss gain share opportunities.

“All of this helps us to run the business efficiently and drive down costs,” he continues. “Other areas where I really feel we should be moving to and are currently engaging in is the use of generating steam for our brewing operations as opposed to using refinement oil. This will reduce our carbon emissions and help us meet UN goals.”

See also:

- ECOM: Enriching the agriculture industry in Ghana

- How Dubai-based startup Fetchr is revolutionising the world of shipment and delivery

- King Abdullah University of Science and Technology’s approach to continuous improvement

Importation challenges

Nonetheless, importing cross-border business, trade barriers, lead times and distribution are all challenges UBL continues to face across its sourcing and procurement capabilities.

“Raw material which is moving less than 500 miles is treated differently from material sourced locally. It’s another challenge entirely when you go out of the African region and import materials from outside of Asia and in Europe,” notes Muwema.

“There's also the challenge of foreign exchange. The shilling for the last six months has depreciated by over 25%, for example, which can significantly impact business.” Increased congestion times at the port of Mombasa can also create inefficiencies in the chain.

“Locally, the key challenge for us is price fluctuation of raw materials,” adds Muwema. “In peak time during harvest prices it drops but rises fast if there are problems such as diseased crops or drought. We also have challenges surrounding distribution fuel surcharges, where pump prices keep shooting up. Nevertheless, we put measures in place to try and mitigate this.”

By sourcing materials locally for its packaging requirements, UBL has therefore worked to reduce and mitigate such barriers to trade, importation and transit times, whilst improving the planning of materials which are sourced from overseas.

Inspiring others

Housing a number of category managers across its procurement team, in areas such as raw materials and packaging, indirect, demand, its Capex projects and more, Muwema’s passion for seeing his team thrive is clearly illustrated throughout our conversation. By growing the fundamental structure of UBL’s nine-person strong procurement team through rotation, the team has gained a diverse skill set and raised morale across the division.

“If we are to be the most trusted company in the country, we should be investing in our people,” explains Muwema.

“We 'inspire through purpose,'” he adds enthusiastically. “What we've really brought to the table is integrity, which is something that the company takes pride in. I think my love for people and mentoring has also rubbed off on my team members, colleagues and peers, so it is something that I'm really proud of.”

So, what does the future then hold for Uganda Breweries?

With future investment in large infrastructure projects in Uganda, such as dams for electricity generation, the country will continue to witness a boost in economic growth and industrialisation. The country will also undergo oil exploration in 2022, which Muwema notes, “will further change the landscape”.

“The future is bright for us,” Muwema confidently concludes. “I see us remaining a major player in the market because we are a very dynamic company. Year on year we've put the right plan in place and take advantage of opportunities which arise. We also have a great portfolio of products as we keep innovating.

“There is a bright future for the country and for the business as we remain a major player in the market.”

- $4.2mn in funding for Nigerian Agritech startup ReleafFood

- Yum! Brands delivers Pizza Hut to Africa, combining global standards with local flavour

- International Breweries to open $250mn facility in NigeriaDrink

- Africa's hotel sector has the potential to grow over the next five years - reportHotels & Hospitality